Commercial Roof Maintenance: Protecting Your Investment

Your Commercial Roof: A Critical Business Asset

Your commercial roof represents one of your property's most significant investments, often accounting for 30-40% of your building's total value. In the Lehigh Valley's challenging climate, where we experience everything from heavy snow loads to intense summer heat, protecting this investment through proper maintenance isn't just recommended—it's essential for business continuity and financial stability.

Commercial roofing systems in Pennsylvania face unique challenges that require specialized attention. From flat membrane systems common in retail and industrial buildings to pitched roofs on office complexes, each requires a tailored maintenance approach. The key is understanding that preventive maintenance costs significantly less than emergency repairs or premature roof replacement.

Understanding Flat vs. Pitched Commercial Roof Maintenance

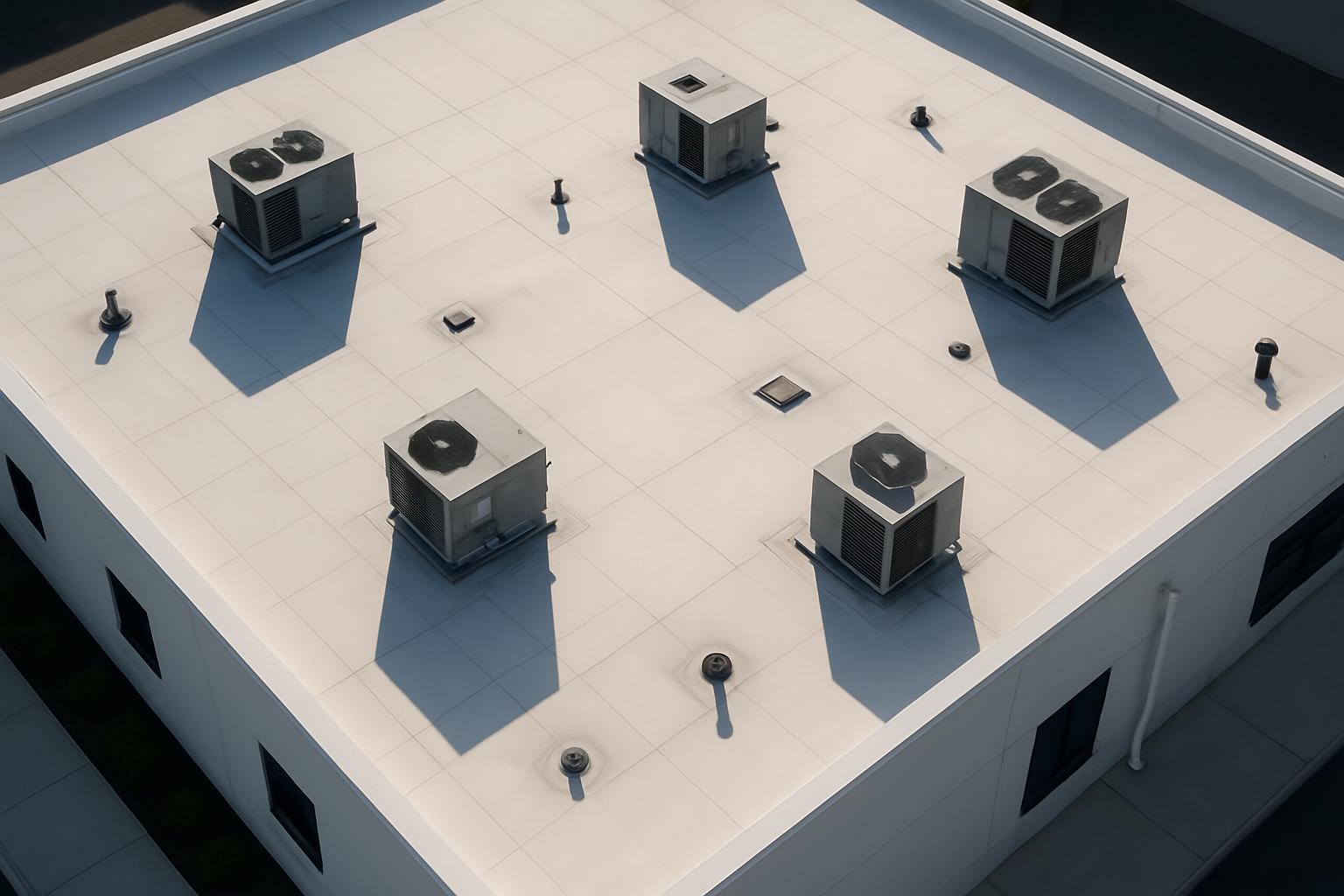

Flat Roof Systems: The majority of commercial buildings in the Lehigh Valley feature flat or low-slope roofing systems, including EPDM rubber, TPO, modified bitumen, and built-up roofing. These systems are particularly vulnerable to ponding water, which can lead to membrane deterioration and structural damage. Flat roofs require more frequent drainage inspections and membrane assessments due to their inability to shed water naturally.

Common flat roof maintenance needs include drain clearing, membrane seam inspection, and ballast or coating assessment. The lack of natural water runoff makes these systems more susceptible to debris accumulation and vegetation growth, which can compromise the roof's integrity over time.

Pitched Commercial Roofs: Sloped commercial roofs, often found on office buildings and mixed-use developments, typically feature metal, asphalt shingles, or tile systems. While these roofs naturally shed water more effectively, they present their own maintenance challenges, including flashing failures around penetrations, gutter system maintenance, and shingle or panel replacement due to weather damage.

The slope advantage of pitched roofs means less standing water concerns, but they require different inspection techniques and safety considerations. Areas where different roof planes meet, along with penetrations for HVAC equipment and skylights, need special attention during maintenance visits.

Implementing a Seasonal Commercial Roof Inspection Schedule

Spring Inspection (April-May): After Pennsylvania's harsh winters, spring inspections focus on identifying winter damage. Look for loose or damaged membrane areas, clogged drainage systems from snow melt debris, and any structural issues from ice dam formation. This is also the ideal time to assess and repair any damage before the summer storm season begins.

Spring maintenance should include thorough drain cleaning, vegetation removal, and membrane inspection for punctures or separations that may have occurred during freeze-thaw cycles. Any discovered issues should be addressed immediately to prevent water infiltration during spring rains.

Summer Inspection (July-August): Summer heat can cause significant expansion and contraction in roofing materials. Focus on membrane bubbling, seam separation, and HVAC equipment mounting integrity. The extreme temperatures common in summer also make this an ideal time to assess the roof's energy efficiency and consider reflective coatings to reduce cooling costs.

Fall Inspection (September-October): Pre-winter preparation is crucial for Lehigh Valley commercial roofs. Clear all drains and gutters of fall debris, inspect and repair any loose or damaged materials, and ensure proper insulation and ventilation systems are functioning correctly. This inspection should also include a comprehensive check of all roof penetrations and flashing systems.

Winter Monitoring (December-February): While comprehensive inspections may be weather-dependent, winter monitoring should focus on ice dam formation, snow load assessment, and ensuring proper interior temperature control to prevent condensation issues. Emergency response capabilities should be maintained for severe weather events.

Identifying and Addressing Common Problem Areas

Drainage System Failures: Poor drainage is the leading cause of premature commercial roof failure. Blocked drains, inadequate slope, and damaged scuppers can lead to ponding water that compromises membrane integrity and increases structural loads. Regular drain cleaning and proper slope maintenance are essential, especially in areas prone to debris accumulation.

Flashing and Penetration Issues: Roof penetrations for HVAC equipment, vents, and utilities create potential water entry points. Flashing around these penetrations requires regular inspection and maintenance. Cracked sealants, loose flashing, and improperly installed penetrations account for nearly 70% of commercial roof leaks.

Membrane Damage and Deterioration: UV exposure, thermal cycling, and physical damage from foot traffic or debris can compromise roofing membranes. Small punctures or tears can quickly expand if not addressed promptly. Regular membrane inspection should include checking for bubbles, cracks, or separation at seams.

HVAC Equipment-Related Problems: Rooftop HVAC units create unique maintenance challenges, including vibration damage to mounting systems, condensation issues, and access-related wear to the roofing system. Proper equipment maintenance and roof protection measures are essential for preventing costly damage.

Preserving Manufacturer Warranties Through Proper Maintenance

Most commercial roofing warranties require documented regular maintenance to remain valid. Manufacturer requirements typically include annual professional inspections, prompt repair of identified issues, and detailed maintenance records. Failure to maintain proper documentation can void warranties worth tens of thousands of dollars.

Professional maintenance programs ensure warranty compliance while providing the documentation necessary to support warranty claims. This includes photographic evidence of maintenance activities, repair records, and professional assessment reports that demonstrate proactive care of the roofing system.

Working with licensed roofing contractors like Conrad General Contracting (PA HIC #PA154190) ensures that maintenance activities meet manufacturer specifications and warranty requirements. Our commercial roofing maintenance programs are designed to protect both your investment and your warranty coverage.

Emergency Preparedness and Response Planning

Severe weather events in the Lehigh Valley can cause sudden roof damage requiring immediate attention. Develop an emergency response plan that includes contractor contact information, temporary protection measures, and damage assessment procedures. Quick response to storm damage can prevent minor issues from becoming major problems.

Emergency preparedness should include identifying trusted roofing contractors available for 24/7 emergency services, maintaining emergency repair materials on-site, and having clear protocols for building occupant safety during roof emergencies.

Conrad General Contracting: Your Commercial Roofing Partner

As licensed Pennsylvania contractors (PA HIC #PA154190), Conrad General Contracting specializes in comprehensive commercial roofing services throughout the Lehigh Valley. Our preventive maintenance programs are designed to maximize your roof's lifespan while minimizing unexpected repair costs. Contact us at (610) 801-0000 for a professional assessment of your commercial roofing needs.